by Jonathan Vatner

Performance fibers—which can stretch, repel water, and take on fluorescent hues—make clothing a lot more comfortable, safe, flattering, and fun. Unfortunately, producing these “miracle fibers” is devastating to our environment, flooding rivers with toxic chemicals and spreading microplastics into oceans.

In 2018, three Textile Development and Marketing students—Valentina Gomez ’20, Morgana Kattermann ’19, and Chui-Lian Lee ’18—set out to engineer biodegradable performance fibers without toxicity. Their team, Werewool, competed in the 2018 Biodesign Challenge, a global undergraduate biotechnology competition that FIT won in 2016. Theanne Schiros, assistant professor of Science, who acted as campus coordinator and faculty adviser for the Biodesign Challenge program, was so excited by Werewool’s possibilities, she joined the team as a co-founder in 2019.

This spring, their four-member startup attracted international attention from both the science and business communities by winning a 250,000-euro Global Change Award, a sustainable innovation challenge initiated by the H&M Foundation. Werewool was one of five winners out of nearly 6,000 entries from 175 countries.

Werewool is harnessing the tools of synthetic biology to design protein fibers with performance properties inspired by organisms in nature.

“In nature, proteins are responsible for all sorts of amazing functional properties,” Schiros says. “Organisms evolve them for survival, UV protection, or to ward off predators. We’ve been coding these proteins to be part of a textile fiber.”

For example, casein, a milk protein, is water-resistant. What if that protein could be grown in a lab as fiber with its waterproof properties intact? Elastin is a stretchy protein found in connective tissue. If that protein could be mass-produced and turned into a fiber, it could replace spandex, a petroleum-based fiber that renders clothing non-recyclable. And almost every color we wear is found in nature; with those proteins, fibers could be produced with the color built in, skirting the toxic, water-intensive dyeing process.

“There are more possible combinations of proteins from different organisms than there are stars in the galaxy,” Schiros says. “This takes sustainability from being limiting—what you can’t do—to being expansive, a really exciting platform for innovation.”

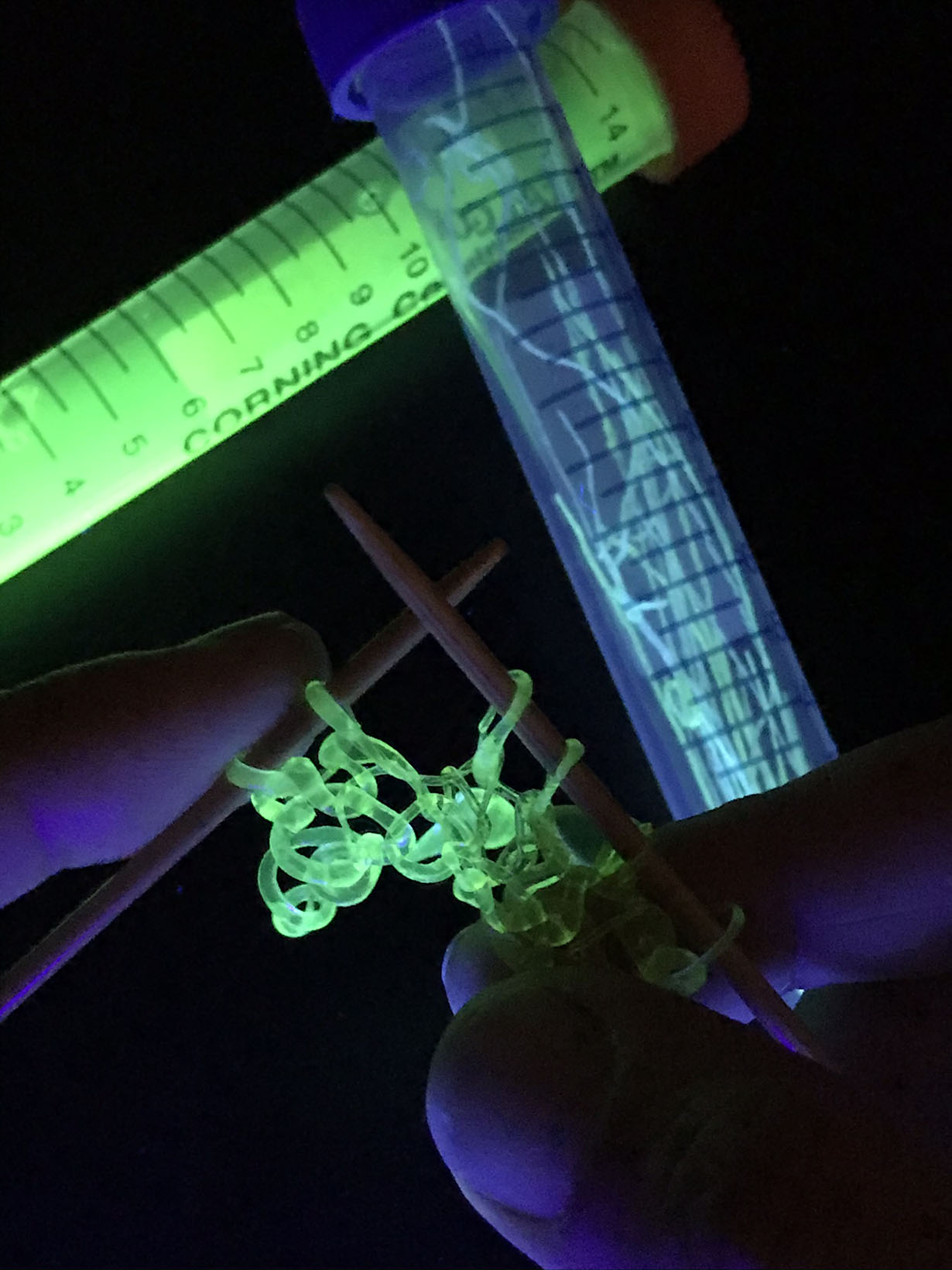

The research follows the protocols of synthetic biology, a field devoted to engineering organisms to sustainably produce proteins that could be used in a range of industries. First, the Werewool team isolates the genome of the functional protein in question (such as the red fluorescent protein that gives coral its bright color), then inserts the DNA plasmid into E. coli microbes, which produce that protein as they multiply.

“There are more possible combinations of proteins from different organisms than there are stars in the galaxy.”

Theanne Schiros

“We use microbes as raw material factories, to produce the feedstock of our fibers,” Schiros explains. “It’s the basics of protein engineering.”

Then they cross-link the proteins they created to strengthen them, and finally extrude a fiber. Their challenge is to make the fibers strong enough to create a sturdy textile, and then scale up production for manufacturing.

“Proteins in nature are goopy molecules,” Schiros explains. “Our big breakthrough was to link them together to form a fiber with the function intact. If we can scale that to actual fibers, it’s potentially revolutionary. We could make, for example, hot pink disco pants that are biodegradable and low-impact.”